Material Analysis using XDAL 237

Product Details:

- Material Industrial grade metal housing

- Condition New

- Technology Energy Dispersive X-ray Fluorescence (EDXRF)

- Portable Yes (Bench-top Unit)

- Light Source X-ray tube

- Pressure Range Atmospheric to 1.2 bar

- Operating Temperature 10C to 40C

- Click to View more

Material Analysis using XDAL 237 Price And Quantity

- 1 Piece

Material Analysis using XDAL 237 Product Specifications

- New

- High-resolution digital imaging

- High-precision silicon drift detector (SDD)

- 10C to 40C

- Yes (Bench-top Unit)

- 0.1 999

- Digital display with intuitive user interface

- 545 x 385 x 400 mm

- Energy Dispersive X-ray Fluorescence (EDXRF)

- X-ray tube

- Up to 1,200 measurements/hour

- AC Power Supply

- X-ray range, 8 keV 40 keV

- Approx. 80 W

- ~30 kg

- Atmospheric to 1.2 bar

- 5-85

- For Non-Destructive Material Analysis

- Industrial grade metal housing

- Micro-focus beam spot for enhanced resolution

- 100240 V AC, 50/60 Hz

Material Analysis using XDAL 237 Trade Information

- 1 Piece Per Day

- 3-4 Week

Product Description

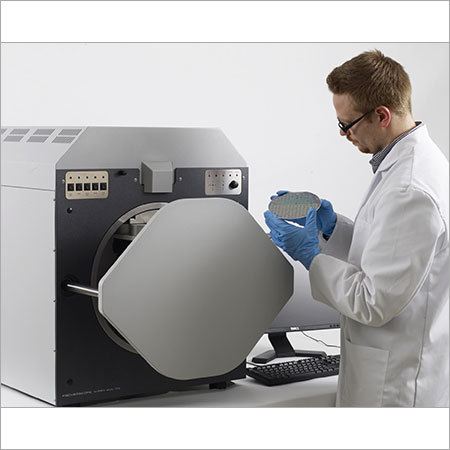

FISCHERSCOPE X-RAY XDAL 237

X-Ray Fluorescence Measuring Instrument with a Programmable XY-Stage and Z-Axis for Automated Measurements of thin Coatings, Watches , fashion Jewellery and for Material Analysis

| Application | Material Analysis |

| Features | The FISCHERSCOPE X-RAY XDAL 237 is a universally applicable energy dispersive x-ray fluorescence measuring instrument. It is especially well suited for non-destructive measurements and analysing very thin coatings, even with very complex compositions or small concentrations as well as automated measurement tasks. With its fast, programmable XY-stage, it is the fitting measuring instrument for automated measurements in quality assurance and production monitoring. |

| Design | The FISCHERSCOPE X-RAY XDAL 237 is designed as a user-friendly bench-top instrument. It is equipped with a high-precision, programmable XY-stage and an electrically driven Z-axis. The sample stage moves into the loading position automatically, when the protective hood is opened. A laser pointer serves as a positioning aid and supports the quick alignment of the sample to be measured. |

| Specification | Intended use Energy dispersive x-ray fluorescence measuring instrument (EDXRF) to determine thin coatings, trace elements and alloys. |

| X-Ray Detection | X-ray detector Silicon PIN detector with peltier cooling |

| X-Ray Source | X-ray Tube X-ray tube Micro-focus tungsten tube with beryllium window |

|

Sample Stage | Design Programmable, motor-driven XY-stage Usable sample placement area Width x depth [mm]: 300 x 350 mm, [in]: 12 x 14 Max. sample weight 5 kg, with reduced approach travel precision 20 kg Max. sample height 140 mm (5.5 in) Max. Travel X/Y-axis: 255 x 235 mm (10 x 9 in); Z-axis: 140 mm (5 in) Max. travel speed 80 mm/s (3.2 in/s) Repeatability precision X/Y unidirectional 0.01 mm (0.4 mils), unidirectional |

| Dimensions | External dimensions Width x depth x height [mm] 570 x 760 x 650 mm, [in]: 22 x 30 x 26 |

Comprehensive Material Analysis in Seconds

Harnessing EDXRF technology, the XDAL 237 provides reliable elemental quantification and mapping for diverse materials. The device supports various sample geometries and offers precision at ppm detection limits, ensuring robust results for quality control, alloy verification, and compliance testing.

Designed for Efficiency and Safety

With an impressive throughput of up to 1,200 measurements per hour and advanced safety features, the XDAL 237 allows continuous, secure operation. The intuitive touchscreen interface streamlines workflows, while the industrial-grade housing guarantees durability in laboratory or production settings.

Flexible Integration and Smart Data Handling

The XDAL 237 simplifies calibration via automatic and user-defined options. Data is easily exported via USB, Ethernet, or printed reports, ensuring seamless integration with existing processes. Its sophisticated software supports both qualitative and quantitative analyses for informed decision-making.

FAQs of Material Analysis using XDAL 237:

Q: How does the XDAL 237 analyze different types of materials?

A: The XDAL 237 uses advanced Energy Dispersive X-ray Fluorescence (EDXRF) technology, combined with micro-focus beam and a high-precision silicon drift detector, to analyze solids, flat, or irregular samples non-destructively. It quantifies elemental composition from Aluminum (Al) to Uranium (U), making it suitable for various industrial applications.Q: What measurement modes are available, and when should each be used?

A: The instrument offers single-point, multi-point, and mapping analysis modes. Single-point is ideal for spot analysis, multi-point for batch checking, and mapping mode for comprehensive spatial distribution studiesuseful for analyzing larger or inhomogeneous samples.Q: Where can the XDAL 237 be deployed for optimal performance?

A: Designed as a portable bench-top unit, the XDAL 237 is suitable for quality control laboratories, manufacturing floors, and research centers. Its rugged industrial metal housing and flexible data outputs support seamless integration into various industrial and laboratory environments across India.Q: What is the process for calibrating the XDAL 237?

A: Calibration can be performed automatically with built-in routines or manually through user-defined parameters, ensuring precise results tailored to specific material types or analytical needs. This flexibility allows users to maintain accuracy for both routine and specialized analyses.Q: How does the integrated analytical software enhance the user experience?

A: The advanced software provides real-time quantitative and qualitative analysis, intuitive digital displays, and easy navigation via a 10-inch touchscreen. Users can interpret results quickly, enabling efficient decision-making for quality assurance or compliance documentation.Q: What are the primary benefits of using the XDAL 237 for non-destructive testing?

A: The XDAL 237 delivers rapid, high-precision elemental analysis without damaging samples, supporting up to 1,200 tests per hour. Its low detection limits and ability to handle a range of sample shapes ensure versatile application, while robust safety and data management features provide reliability and traceability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Material Analysis Instruments' category

|

Fischer Measurement Technologies (India) Pvt. Ltd. Fischer Measurement Technologies (India) Pvt. Ltd. Fischer Measurement Technologies (India) Pvt. Ltd. |

Fischer Measurement Technologies (India) Pvt. Ltd. Fischer Measurement Technologies (India) Pvt. Ltd. Mumbai: 9724312808 / 9324639406 Ahmedabad: 9724312808 / 9099086111 |

Send Email

Send Email

Call Me Free

Call Me Free